How to Choose the Right Labels to Print for Your Needs?

Choosing the right labels to print can significantly impact your business identity. Labels convey essential information about your products. They serve not just for identification but also for marketing.

When selecting labels to print, consider your specific requirements. Think about size, material, and design. For instance, a durable label is vital for products exposed to moisture. Clear labels might enhance the aesthetic for premium items.

However, many people overlook the importance of functionality. A beautiful design may not work if the label peels off easily. Reflect on your past choices. Were they effective? Understanding your audience can guide your label decisions. Effective labels to print connect with consumers and help in brand recognition.

Understanding Your Label Requirements and Printing Needs

When choosing labels, it's crucial to understand your needs. How will you use these labels? Are you labeling products, organizing files, or branding items? Each application has different requirements. For instance, food labels need to be waterproof and resistant to oil, while shipping labels require durability for rough handling.

Tips: Assess your environment. Consider where the labels will be placed. Indoor labels might work well with standard adhesives, while outdoor labels need stronger options. Think about weather conditions.

Another point is the material. Paper labels are cost-effective but not great for durable use. Plastic labels are stronger and withstand more wear. Yet, they can be more expensive, so balance quality with your budget. If you’re unsure, order samples to test. This helps identify the right choice without much commitment.

Remember, not every label will suit your needs perfectly. It’s okay to make mistakes. Every choice teaches you something for future projects. Reflect on your label experiences to refine your requirements.

Exploring Different Types of Labels for Various Applications

When it comes to choosing labels, understanding their types is crucial. Different applications need specific features. For instance, waterproof labels work well for products exposed to moisture. This is important in food packaging or outdoor items. On the other hand, thermal labels are perfect for shipping and logistics. They simplify the labeling process and can save time.

Tips: Consider your label's environment. Will it face heat, cold, or moisture? Make your selection based on these conditions.

Moreover, custom labels offer versatility. You can personalize them for branding or instructions. However, note that custom options can add to costs. Balance your budget with your needs. Reflect on whether spending more on branding is worth it for your goals.

Tips: Always order samples if unsure. Testing labels can help avoid costly mistakes later. Look for durability in your chosen label type.

Factors to Consider When Selecting Label Materials and Adhesives

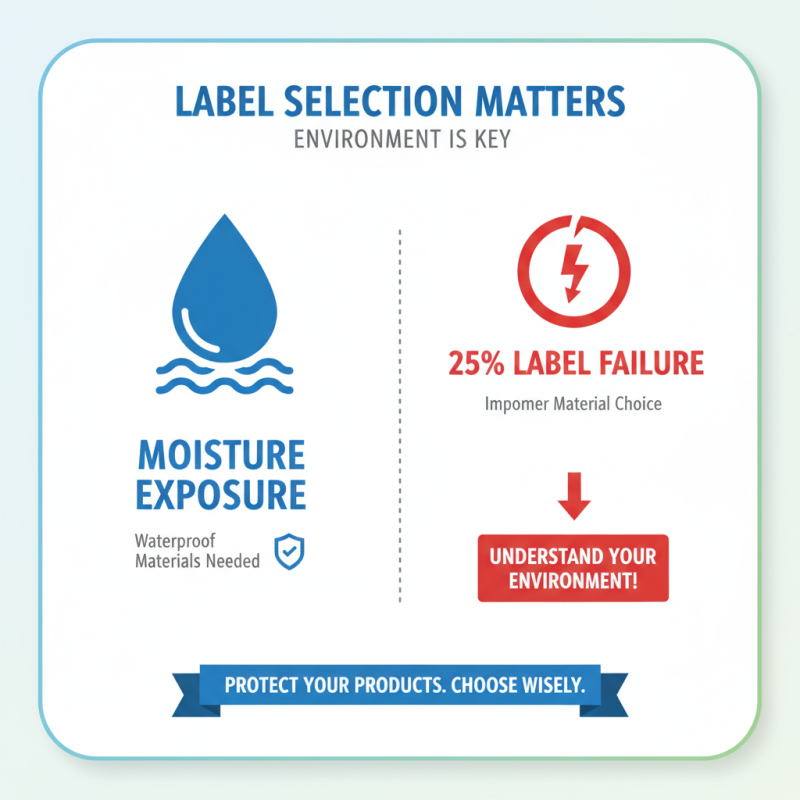

When selecting label materials and adhesives, it's essential to consider various factors. One key aspect is the environment where labels will be used. For instance, labels exposed to moisture require waterproof materials. According to industry reports, about 25% of labels fail due to improper material selection. This statistic highlights the importance of understanding your environment.

Adhesive types also play a crucial role. Pressure-sensitive adhesives are common but might not suit all applications. A report indicated that 30% of adhesive-related issues stem from mismatched substrates. It’s vital to know the surface you’re applying labels to. Different surfaces react uniquely to adhesives, which can lead to adhesion failures.

Cost is another factor to evaluate. Choosing a cheaper material might save money now but could lead to additional costs later. The durability of labels can influence overall expenses. Studies show that businesses can save around 15% by investing in higher-quality materials upfront. It’s a paradox—spending more initially might prevent future losses.

Choosing the Right Label Size and Shape for Your Project

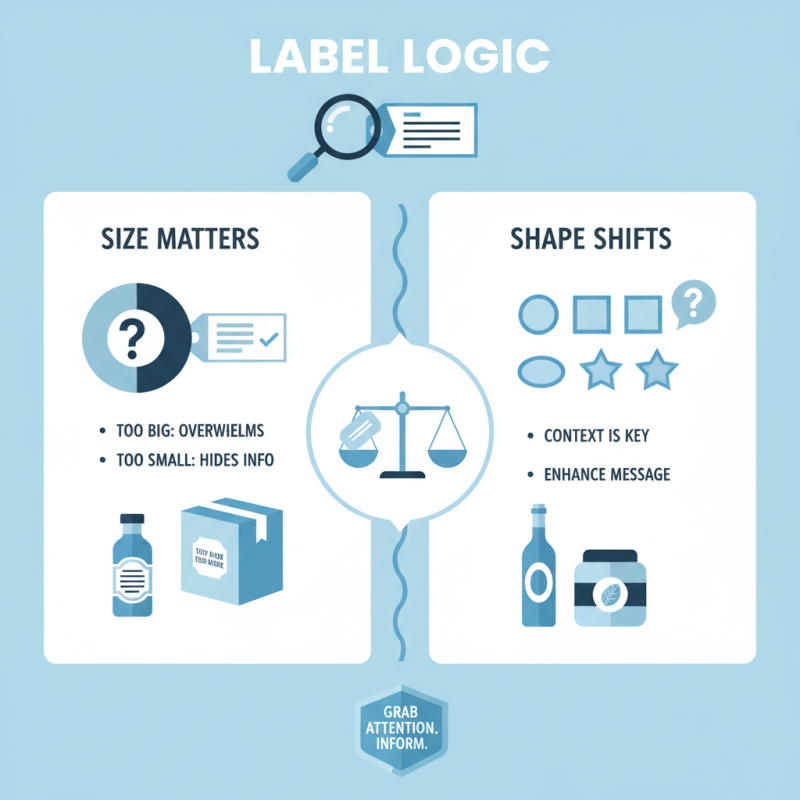

Choosing the right label size and shape is critical for any project. A perfect label grabs attention and conveys information effectively. Think about the context where the label will be used. How big or small should it be? If it’s too large, it may overwhelm the product. If it's too small, vital information might be lost.

Consider the shape as well. Round labels often add a playful touch, while rectangular ones offer a more traditional feel. The shape can also influence how the label adheres to surfaces. Standard shapes are easier to manage, yet custom shapes can stand out. It's crucial, though, to ensure the shape matches the purpose of your product.

Reflect on your project’s goals. Are you looking for elegance or boldness? A mismatch in size or shape can lead to confusion. Test your choices with a few samples. Observe how others respond. Sometimes, getting feedback from different perspectives can reveal aspects you had not considered. Don’t hesitate to make adjustments based on what you see.

Evaluating Printing Methods for Optimal Label Quality and Durability

Choosing the right printing method for labels is crucial. It impacts quality, durability, and cost. Some common methods include digital, flexographic, and screen printing. Each has its advantages and limitations, making it essential to evaluate your specific needs.

Digital printing offers quick turnaround and flexibility. It is ideal for small batches. However, it may lack durability in harsh environments. On the other hand, flexographic printing excels in large runs. Its vibrant colors last longer, making it suitable for products exposed to light and moisture. Yet, setup costs can be a drawback.

Screen printing is another option. It is great for bold designs and textures. The colors are vibrant and can withstand wear. Yet, it may not be as efficient for intricate details. Additionally, some materials may not respond well to this method. Thus, testing different methods and materials is essential. Reflecting on these options will guide you to make the right choice.

How to Choose the Right Labels to Print for Your Needs?

| Label Type | Printing Method | Durability | Best Use Case | Cost Efficiency |

|---|---|---|---|---|

| Paper Labels | Inkjet | Low (1-3 years) | Retail Products | Low |

| Vinyl Labels | Laser | High (3-5 years) | Outdoor Use | Moderate |

| Polyester Labels | Thermal Transfer | Very High (5+ years) | Industrial Applications | High |

| BOPP Labels | Flexographic | Medium (2-4 years) | Food Packaging | Moderate |

| Static Cling Labels | Digital Printing | Low (1 year) | Temporary Displays | Low |

Related Posts

-

Top 10 Benefits of Printing Labels for Your Business Needs?

-

10 Essential Tips for Effective Labels Printing to Boost Your Business

-

2025 How to Make Labels: A Complete Guide for Easy Label Creation

-

How to Make Labels at Home Using Easy Methods and Creative Ideas

-

Top 10 Best Print Packaging Labels for Your Business Success?

-

2025 Top 10 Labels Printing Innovations You Can't Miss