How to Choose the Best Pressure Sensitive Labels for Your Business Needs

In today's competitive marketplace, selecting the right pressure sensitive labels is crucial for ensuring product visibility and customer engagement. According to a recent report by Smithers Pira, the global pressure sensitive label market is projected to reach an impressive $52 billion by 2024, illustrating the importance of these labels in driving brand success. With various materials, adhesives, and printing technologies available, businesses must carefully assess their specific needs to capitalize on this growth opportunity.

Industry expert Dr. John McHugh, a leading researcher in label technologies, emphasizes the significance of making informed choices: "The proper selection of pressure sensitive labels can significantly enhance product appeal and operational efficiency." This insight highlights the necessity for businesses to understand the diverse applications and potential cost implications of different labeling solutions. By considering factors such as durability, environmental impact, and compatibility with various surfaces, companies can tailor their labeling strategies to align with their branding and operational goals effectively. Making the right decision in choosing pressure sensitive labels not only enhances product differentiation but also contributes to overall business performance.

Understanding Pressure Sensitive Labels and Their Uses

Pressure sensitive labels are versatile adhesive materials that do not require heat or water to adhere to surfaces. They consist of three essential components: the facestock, the adhesive, and the liner. The facestock is the top layer that can be printed on or customized with designs, while the adhesive is what ensures these labels stick to various substrates. The liner, usually made of paper or plastic, provides a protective backing that makes application easier. Understanding these components is crucial for selecting the right labels that will fulfill specific business requirements.

These labels are used across various industries for a multitude of purposes, including product labeling, packaging, and branding. They can be designed to withstand different environmental conditions, making them suitable for indoor and outdoor applications. For instance, some pressure sensitive labels offer additional features such as water resistance, UV protection, or tamper-evidence, depending on the needs of the product they will be attached to. By evaluating the intended use and environment, businesses can make informed decisions to choose labels that enhance their product presentation and durability.

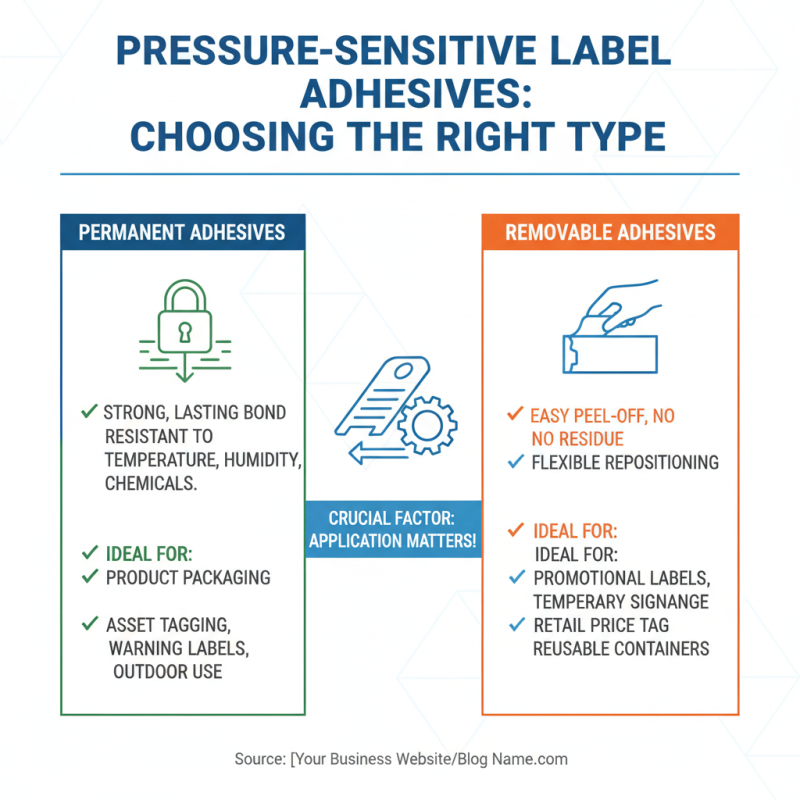

Evaluating Different Types of Adhesives for Labels

When selecting pressure sensitive labels for your business, the type of adhesive used is a crucial factor that can impact the label's performance and longevity. Different adhesives are designed for specific applications, ensuring that labels adhere properly under various conditions. For instance, permanent adhesives are ideal for situations where a strong bond is necessary, while removable adhesives provide flexibility for applications requiring easy label removal without leaving residue.

Tips: Consider the environment in which your labels will be used. For outdoor products or items exposed to moisture, opt for adhesive materials that can withstand harsh conditions. Conversely, if your labels will be applied to surfaces that may need re-labeling, a removable adhesive could be the better choice.

Additionally, it's important to evaluate the surface type where the labels will be applied. Some adhesives bond better with smooth surfaces, while others are formulated to adhere to textured or difficult surfaces. Testing different adhesives on your substrate can help determine the best match for your needs, ensuring that your labels perform as expected.

Assessing Material Choices for Durable Labeling Solutions

When choosing pressure sensitive labels for your business, the material of the label is crucial to ensuring durability and performance. The most common materials include paper, vinyl, and polyester, each offering distinct advantages depending on the application.

Paper labels are cost-effective and suitable for short-term use or indoor applications. However, they may not withstand moisture, oil, or extreme temperatures, making them less ideal for products exposed to harsh conditions.

On the other hand, vinyl labels offer superior resistance to water and chemicals, making them a popular choice for outdoor applications or products that require longevity. They are flexible and can adhere well to irregular surfaces, ensuring a secure bond.

Polyester labels provide an excellent balance between durability and cost, often featuring a strong adhesive that works well in various environments.

Further considerations include adhesive types, which can impact how well the label adheres to the intended surface and its resistance to peeling or lifting over time.

By carefully assessing these material choices, businesses can select labels that not only meet their immediate needs but also contribute to long-term branding and product integrity.

Determining Label Size and Shape for Your Specific Applications

When selecting pressure sensitive labels for your business, understanding the intricacies of label size and shape is crucial for ensuring optimal application and effectiveness. According to a recent market analysis by Smithers Pira, the global market for pressure sensitive labels is projected to reach $49 billion by 2023, emphasizing the significant impact that properly chosen labels can have on branding and customer engagement. One report highlights that nearly 50% of consumers say that the label plays a pivotal role in their purchasing decision, demonstrating the necessity of not just appealing visuals but also a functional design tailored to the specific product.

Determining the right size and shape of your labels involves several considerations. First, consider the dimensions of the packaging and the intended surface—labels must fit seamlessly without wrinkling or peeling. The study by AWA Alexander Watson Associates indicates that labels that cover at least 30% of a product's surface can enhance visibility and brand recall significantly. Ideal label shapes vary depending on container type; for example, round labels work well on cylindrical bottles, while square or rectangular labels are often more suitable for flat surfaces. Moreover, the selection of die-cut shapes can also convey a distinctive brand image, and distinctiveness can boost user recognition by up to 15%, according to recent industry research.

Integrating these insights into your label strategy will not only facilitate functional performance but also enhance the overall consumer experience, driving success in a highly competitive market.

Considerations for Customization and Branding on Labels

When selecting pressure-sensitive labels for your business, customization and branding are crucial aspects to consider. The label serves not only as a functional tool for information but also as a reflection of your brand identity. Choosing colors, fonts, and designs that align with your overall branding strategy can significantly enhance brand recognition and customer loyalty. Ensure that the elements you select resonate with your target audience, as a well-designed label can effectively communicate your brand's values and appeal to consumer preferences.

Additionally, the material and finish of your labels play an essential role in customization. Options range from matte and glossy finishes to various materials that can withstand different environmental conditions. Choosing the right substrate not only affects the durability of the label but also influences how the colors and designs appear. Consider how the label will be used and the conditions it will face, as this will guide you in making choices that reinforce your brand's professional image while ensuring functionality. Properly customized pressure-sensitive labels can elevate your product and create a lasting impression, ultimately contributing to your business success.

Pressure Sensitive Labels Customization Factors

This bar chart illustrates the importance of various customization factors when selecting pressure sensitive labels for business needs. Each factor is rated on a scale from 1 to 10, helping businesses prioritize their requirements for effective labeling.

Related Posts

-

Top Trends in US Printing for 2025: What You Need to Know

-

What is Art Printing and How It Transforms Creative Expression

-

How to Make Labels at Home Using Easy Methods and Creative Ideas

-

10 Essential Tips for Effective Labels Printing to Boost Your Business

-

Top 10 Incredible Benefits of Using You Printing for Your Business Needs

-

10 Best Us Printing Services for High Quality Custom Prints