2026 How to Use Labels to Print Effectively?

In today’s fast-paced business environment, understanding how to effectively use labels to print is crucial. According to a report by Smithers Pira, the global label market is expected to reach $50 billion by 2026. This staggering growth emphasizes the importance of optimized printing practices. Industry expert Mark Stevens states, "Effective label printing can streamline operations and reduce costs." His insights highlight the need for businesses to adapt their strategies.

Many companies struggle with the complexities of labels to print. Issues include design inconsistencies or incorrect materials. These missteps can lead to wasted resources. It is vital for organizations to recognize these common pitfalls and learn from them. For instance, improper label sizes can result in reprints and delays.

Moreover, the variety of label types can be overwhelming. From thermal to inkjet, each method has its own merits. Businesses must reflect on what works best for their specific needs. Adopting a well-researched approach could ultimately enhance productivity and effectiveness in using labels to print.

Understanding Different Types of Labels for Printing

Labels are essential for effective printing. They come in various types, each serving a specific purpose. For instance, there are adhesive labels, which stick to surfaces easily. They are ideal for shipments and organization. Then, there are tags. Tags can be used for products or events and often come with strings. Their versatility cannot be overstated.

Another type is thermal labels. These labels are printed using heat. They are commonly used in retail environments. Small mistakes with thermal printers can lead to wasted labels. It’s crucial to align everything properly. Finally, specialty labels exist for unique needs like waterproof or scratch-resistant applications. These labels may require specific printers. They often have a higher cost.

Understanding these different types of labels is vital. Choosing the wrong label can lead to dissatisfaction. It can be frustrating to see unreadable labels on products. Testing various types can help determine what works best for your project. Each label has its strengths and weaknesses. It's important to evaluate them carefully before making a choice.

Choosing the Right Printer for Label Printing Needs

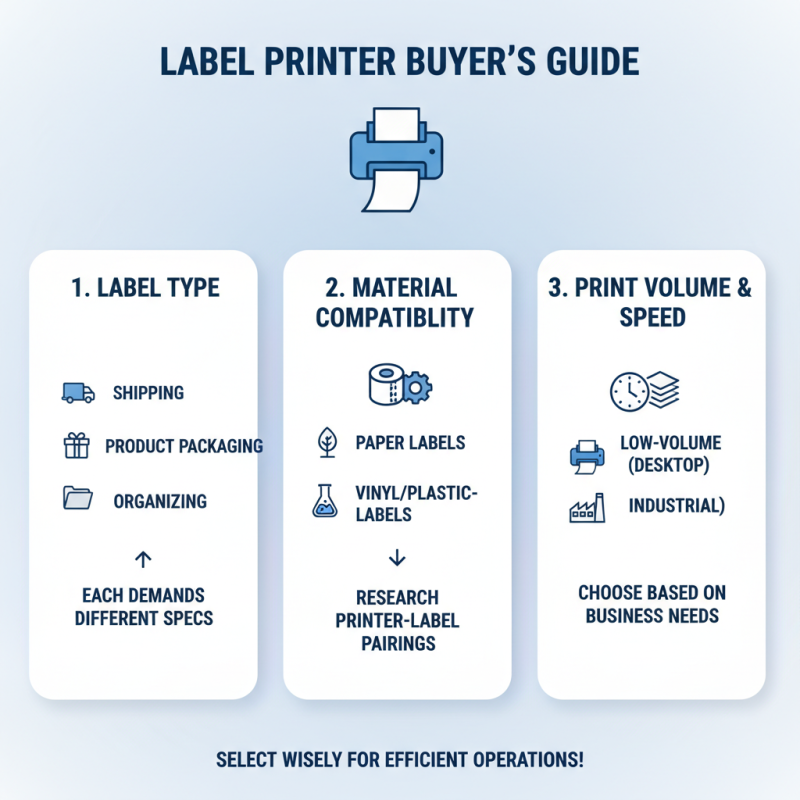

When choosing a printer for label printing, several factors must be considered. The type of labels you need matters. Are they for shipping, product packaging, or organizing? Each application may demand different label specifications. Some printers work better with specific materials. It’s important to research which printers can handle the types of labels you plan to use.

Speed and volume are also crucial. If you require high-volume printing, ensure your printer can keep up. Some machines may promise high output but underdeliver in real situations. Review customer feedback to learn about performance. Don’t get too caught up in technical jargon. Simple features may outweigh advanced ones in practical use.

Think about connectivity options, too. Wireless or USB connections can make a big difference in convenience. But some users struggle to set up these features. Following the instructions can be frustrating for many. It's wise to evaluate your comfort level with technology. This decision affects how efficiently you can run printing tasks. It is easy to overlook these elements, but they can hasten or slow down your workflow.

Designing Labels for Maximum Impact and Clarity

Creating labels that stand out requires careful design. Clear fonts and bold colors are essential. Think about the message you want to convey. Use simple language that everyone can understand. Avoid clutter and keep the layout clean. Your audience should grasp the information quickly.

Identify the key elements that need emphasis. Sizes and spacing matter. A label should be legible from a distance. Experiment with different styles, but don't overdo it. Balance creativity with clarity. Sometimes, less really is more.

It’s important to test your labels. Gather feedback from various people. Are they easy to read? Do they convey the right message? Reflect on their effectiveness. Sometimes, it may not turn out as expected, and that's okay. Use those insights to make improvements. Design is an evolving process. Embrace the imperfections and learn from them.

2026 How to Use Labels to Print Effectively

This chart illustrates the effectiveness of various label features in printing, emphasizing the importance of clarity, design, material quality, color accuracy, and durability.

Steps for Proper Label Placement on Products

Proper label placement is essential for product visibility and customer engagement. Position your labels where they can be easily seen. Front and center is ideal for most products. However, don’t forget about side labels. Sometimes, they can be just as important. Ensure that the information is clear and readable.

Use appropriate sizes and colors for your labels. Too small, and they may get overlooked. Too large, and they can overpower the product. Balance is key. Consider testing different placements. Take photos and review them. Are the labels standing out? Are they cluttered? This evaluation can improve your approach.

Remember to consider the context. For instance, some labels work well on flat surfaces. Others look better on curved ones. Find what suits your product best. Experiment with materials. Transparent labels may not pop on glass containers, while bold colors can draw attention on plain packages. Reflect on what works and what doesn’t. This process can lead to better results.

Common Printing Issues and How to Troubleshoot Them

When printing labels, it's common to encounter various issues. Some labels might not align properly on the sheet. If this happens, check your printer settings. Ensure that you are using the correct label size. A mismatched size often leads to misalignment. It can be frustrating to waste sheets due to simple errors.

Another issue can be smudging or ink running. Poor quality ink or damp labels could be the culprits. Test different paper types or ink cartridges. Adjusting the printer temperature can also help. Sometimes, a trial and error approach is necessary. You might end up with less-than-perfect prints, but each attempt teaches you something new.

Finally, ensure that your printer's software is up-to-date. Outdated software can lead to performance issues. If you experience frequent paper jams, check the paper path for hidden debris. Regular maintenance prevents many problems. Each small step can lead to a smoother printing process, despite occasional setbacks.

Related Posts

-

How to Make Labels at Home Using Easy Methods and Creative Ideas

-

2025 How to Make Labels: A Complete Guide for Easy Label Creation

-

How to Create Effective Product Labels That Attract Customers and Boost Sales

-

Why Are Pressure Sensitive Labels Essential in Modern Packaging Solutions?

-

Top 10 Benefits of Printing Labels for Your Business Needs?

-

Why You Should Order Printed Labels for Your Business Needs?