10 Essential Tips for Optimizing Your Industrial Printing Processes

In today's competitive market, optimizing industrial printing processes has become crucial for businesses aiming to increase efficiency and reduce costs. With advancements in technology and the ever-evolving demands of clients, professionals in the industrial printing sector must adapt and refine their approaches to ensure maximum productivity. According to John Smith, a leading expert in industrial printing, "The future of industrial printing lies in our ability to continuously streamline operations and embrace innovation." This statement underscores the importance of not only keeping pace with technological progress but also actively seeking methods to enhance workflow.

As we delve into the essential tips for optimizing industrial printing processes, it is vital to consider various factors that contribute to improved output and quality. From equipment maintenance to staff training, each element plays a significant role in shaping the overall efficiency of printing operations. By implementing effective strategies, companies can minimize waste, reduce turnaround times, and ultimately provide better service to their customers. This article will explore ten critical tips designed to help industry professionals navigate the complexities of modern industrial printing, ensuring they remain competitive in a rapidly changing landscape.

Understanding the Importance of Process Optimization in Industrial Printing

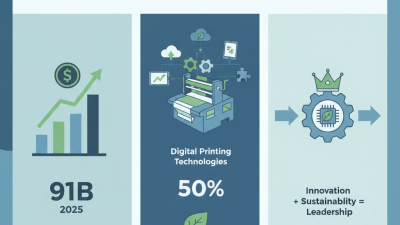

In the competitive realm of industrial printing, process optimization is not merely a trend but a necessity. According to a recent study from Smithers Pira, the global market for printed materials is expected to grow by approximately 3.4% annually, underscoring the importance of efficient operations. Optimizing printing processes involves reducing waste, improving speed, and enhancing quality, all of which contribute to better profit margins and customer satisfaction. A report by the National Association of Printing Ink Manufacturers highlighted that improved workflow and automation can lead to a reduction in production costs by up to 20%, making it critical for businesses to evaluate their operational efficiencies regularly.

Moreover, embracing advanced technologies such as digital printing and real-time data analytics can significantly impact process optimization. As per a survey by the Printing Industries of America, companies that have adopted data-driven decision-making strategies reported a 15% increase in production efficiency. By analyzing production data, businesses can identify bottlenecks, minimize downtime, and optimize ink usage, resulting in a more sustainable operation. These advancements not only streamline manufacturing processes but also position businesses to better meet the evolving demands of the market, ultimately leading to a more robust and adaptable printing operation.

10 Essential Tips for Optimizing Your Industrial Printing Processes

Key Metrics for Measuring Printing Efficiency and Output Quality

Measuring printing efficiency and output quality is crucial for optimizing industrial printing processes. Key metrics such as Overall Equipment Effectiveness (OEE) provide a comprehensive view of how well a printing operation is performing. OEE combines availability, performance, and quality to help managers identify areas needing improvement. For instance, low availability might indicate equipment downtime, while low performance could highlight inefficiencies in the printing speed or setup times. By monitoring these metrics, organizations can pinpoint specific issues that hinder productivity and proactively address them.

Another essential metric is First Pass Yield (FPY), which measures the quality of output by assessing the percentage of products that meet quality standards without needing rework. High FPY figures signify not only effective processes but also reduced waste, which is vital for both operational cost savings and environmental considerations. Tracking this metric facilitates continuous improvement by enabling teams to analyze failures and implement corrective actions swiftly. Together, these key metrics serve as benchmarks that guide industrial printers toward enhanced workflow efficiency and superior product quality.

Adopting Innovative Technologies to Enhance Printing Performance

In today's competitive landscape, adopting innovative technologies is crucial for enhancing the performance of industrial printing processes. The integration of advanced software solutions can streamline workflow management, enabling companies to monitor production schedules and material usage in real-time. This proactive approach reduces downtime and maximizes efficiency, allowing businesses to respond quickly to market demands. Additionally, cloud-based technologies can facilitate easier sharing of designs and documents across teams, ensuring that all stakeholders are aligned and reducing the potential for errors.

Furthermore, exploring the capabilities of high-tech printing equipment plays a vital role in optimizing output quality. Utilizing techniques such as digital and 3D printing can drastically transform traditional methods. These technologies not only improve precision but also offer the flexibility to produce customized products tailored to client specifications. Moreover, investing in automation technologies can significantly enhance productivity by minimizing manual interventions and speeding up the production cycles. Embracing these innovations can lead to an overall enhancement in printing performance, positioning businesses to stay ahead in a rapidly evolving industry.

10 Essential Tips for Optimizing Your Industrial Printing Processes

| Tip Number | Optimization Tip | Expected Outcome | Implementation Difficulty |

|---|---|---|---|

| 1 | Adopt Digital Inks | Improved color accuracy and reduced printing waste | Medium |

| 2 | Implement Workflow Automation | Reduced turnaround time and labor costs | High |

| 3 | Upgrade Printing Equipment | Faster processing speeds and higher quality output | High |

| 4 | Regular Maintenance Schedules | Longer equipment lifespan and fewer breakdowns | Low |

| 5 | Train Staff on Latest Technologies | Increased efficiency and reduced error rates | Medium |

| 6 | Utilize IoT for Real-Time Monitoring | Proactive maintenance and better operational insights | High |

| 7 | Optimize Material Usage | Lower material costs and reduced environmental impact | Medium |

| 8 | Create a Feedback Loop | Continuous improvement and customer satisfaction | Low |

| 9 | Implement Color Management Systems | Consistent colors across print jobs | Medium |

| 10 | Explore 3D Printing Options | Enhanced product offerings and customization | High |

Establishing a Consistent Maintenance Schedule for Printing Equipment

Establishing a consistent maintenance schedule for printing equipment is crucial in optimizing industrial printing processes. Regular maintenance not only extends the lifespan of machinery but also enhances operational efficiency by minimizing the risk of unexpected breakdowns. Scheduling routine inspections and servicing ensures that minor issues are addressed before they escalate into major problems, which can lead to costly downtime and production delays. Developing a checklist for specific equipment needs, including cleaning, lubrication, and component replacements, can streamline this process.

Additionally, integrating predictive maintenance technologies can further improve maintenance schedules. By using data analytics to track printer performance and identify patterns, operators can anticipate potential failures and address them proactively. This approach not only saves time and resources but also helps in maintaining consistent print quality. Regularly updating the maintenance schedule based on equipment usage and performance metrics allows businesses to adapt and respond to their specific operational demands, leading to smoother workflows and increased productivity in the long run.

Training and Development Initiatives for Printing Workforce Optimization

Investing in the training and development of your printing workforce is crucial for optimizing industrial printing processes. A skilled workforce not only enhances productivity but also contributes to overall quality improvements in print output. Implementing regular training sessions tailored to the specific needs of employees fosters a culture of continuous improvement. Workshops that cover the latest printing technologies, equipment maintenance, and troubleshooting techniques can empower workers to handle complexities more efficiently, reducing downtime and waste.

Moreover, fostering an environment that encourages knowledge sharing among employees can lead to innovative solutions and best practices. Peer-led training sessions or mentorship programs can help less experienced workers learn from their seasoned colleagues, promoting teamwork and collaboration. To support this initiative, consider creating a structured development plan that identifies key competencies required in your organization and offers pathways for employees to gain these skills through online courses or in-house training programs. By prioritizing workforce development, companies can ensure that their printing operations are not only optimized but also adaptive to the evolving demands of the industry.

Related Posts

-

What is Craft Labels and How to Use Them for Your DIY Projects

-

10 Best Us Printing Services for High Quality Custom Prints

-

How to Make Labels at Home Using Easy Methods and Creative Ideas

-

2025 Top 10 Labels Printing Innovations You Can't Miss

-

10 Essential Tips for Effective Labels Printing to Boost Your Business

-

Top Trends in US Printing for 2025: What You Need to Know