How to Order Printed Labels for Your Business Efficiently and Cost Effectively

When it comes to running a successful business, every detail counts, from your product quality to your branding efforts. One often-overlooked aspect of this is the importance of labeling. Properly designed and printed labels not only convey critical information about your products but also serve as a marketing tool that can enhance brand recognition. To achieve the best results without breaking the bank, knowing how to order printed labels efficiently and cost-effectively is essential.

The process of ordering printed labels can seem daunting, with a multitude of options in terms of materials, sizes, designs, and printing techniques. However, understanding your specific needs and the available resources can simplify the decision-making process. By approaching the task with a clear strategy, businesses can streamline their orders, reduce waste, and optimize costs. This article will guide you through the key steps in ordering printed labels, ensuring that your choices align with your branding and budgetary goals while maximizing efficiency. Whether you're a startup or an established company, learning how to order printed labels effectively can make a notable difference in your overall operations.

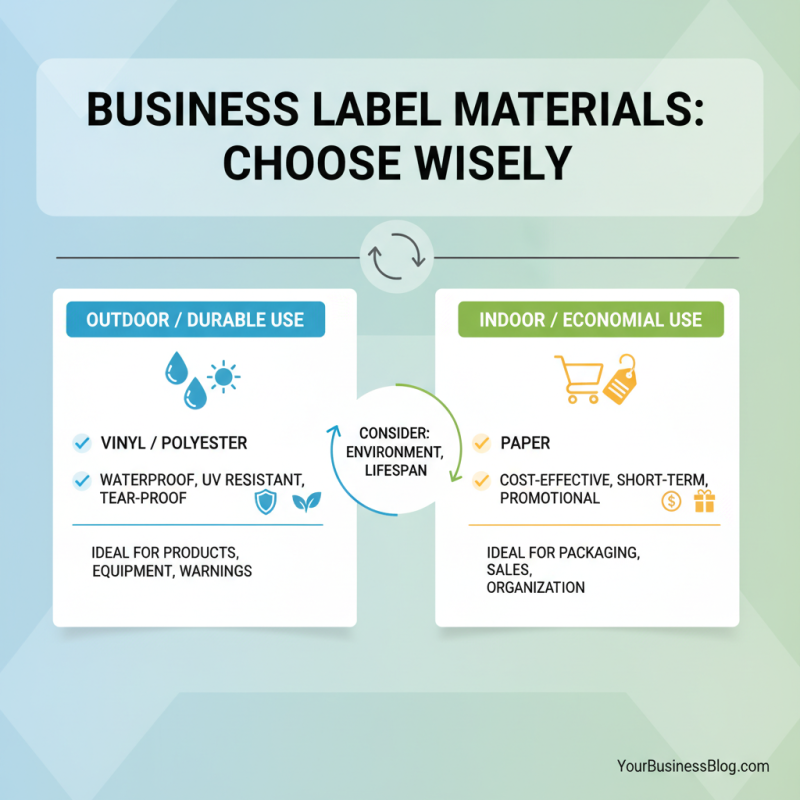

Choosing the Right Label Material for Your Business Needs

When ordering printed labels for your business, selecting the right label material is crucial for both functionality and cost-effectiveness. Different materials offer various benefits, catering to diverse applications and environments. For instance, if your labels will be exposed to moisture or outdoor conditions, waterproof materials such as vinyl or polyester are ideal, as they resist fading and tearing. On the other hand, paper labels can be a more economical choice for indoor use, especially for short-term applications or promotional materials.

In addition to durability, the choice of label material can also impact the printing and design process. Some materials are better suited for high-resolution printing and can deliver vibrant colors, while others may absorb ink differently, affecting the overall appearance. Consider the requirements of your specific use case—adhesives also play a role, with removable options available for labels that may need to be repositioned or taken off cleanly. Assessing these factors will help ensure that the labels not only meet your aesthetic standards but also function effectively within the demands of your business.

Determining the Optimal Label Size and Shape for Your Products

Determining the optimal label size and shape for your products is crucial for ensuring that your branding stands out while effectively communicating important information to your customers. The first step in this process involves understanding the dimensions and characteristics of your product. For various items, such as bottles, boxes, or bags, the label must be proportional to the item itself. An overly large label may overwhelm the product, while a very small label can be easily overlooked.

Furthermore, the shape of the label plays a significant role in how it interacts with the product and catches the eye of potential customers. Traditional rectangular labels may be suitable for most products, but experimenting with unique shapes, such as circles or custom die-cuts, can enhance shelf appeal and convey a distinctive brand identity. Additionally, consider how the label's design interacts with the packaging—rounded edges can complement softer shapes, while angular labels can emphasize a more modern aesthetic. Taking time to assess both size and shape will contribute to more efficient and cost-effective ordering processes, ultimately leading to a better connection with your target audience.

Exploring Different Printing Methods for Cost Efficiency

When it comes to ordering printed labels for your business, the choice of printing method plays a crucial role in achieving cost efficiency. Various techniques can yield different outcomes, influencing both quality and price. For instance, digital printing is often favored for shorter runs due to its affordability and quick turnaround times. This method allows businesses to produce high-quality labels with vibrant colors and intricate designs without the burden of large upfront costs usually associated with traditional printing methods.

Conversely, offset printing may be more suitable for larger batches. While the initial setup costs can be higher, the per-label cost tends to decrease significantly as the quantity increases. This method is particularly advantageous for businesses that have consistent labeling needs, as it provides a cost-effective solution for mass production. Moreover, flexographic printing is another option for high-volume jobs, leveraging fast drying inks to efficiently create labels for packaging. Understanding these printing methods enables businesses to align their label production strategy with their budgetary goals, ensuring that they select the most effective approach for their needs.

Cost Efficiency of Different Printing Methods for Labels

Finding a Reliable Printer: Key Factors to Consider

When searching for a reliable printer for your business's printed labels, it’s essential to consider several key factors that can significantly influence the quality and efficiency of your order. First and foremost, examine the printer's reputation within the industry. Look for reviews and testimonials from other businesses that have utilized their services. A printer with a proven track record of timely deliveries and high-quality outputs can save you potential headaches and ensure your labels meet professional standards.

Next, consider the printing technology and materials used by the printer. Different printers may specialize in various printing techniques, such as digital or offset printing, which can yield different results in terms of quality and durability. It's also crucial to confirm that they can accommodate your specific requirements, such as custom sizes, shapes, and adhesives for your labels. Additionally, inquire about the range of materials available, as this can impact the final appearance and performance of your labels under various conditions, such as weather exposure or surface adhesion.

Lastly, evaluate the printer's customer service and support options. A responsive and knowledgeable support team can provide guidance and assistance throughout your ordering process, helping to resolve any issues that may arise efficiently. Establishing a solid line of communication is vital for ensuring that your needs are met, especially when working on tight deadlines or adjustments in your order specifications. By prioritizing these factors, you can choose a printer that aligns with your business's goals and ensures a smooth ordering experience.

How to Order Printed Labels for Your Business Efficiently and Cost Effectively - Finding a Reliable Printer: Key Factors to Consider

| Printer Criteria | Importance Level | Estimated Cost ($) | Turnaround Time (days) | Customer Reviews (out of 5) |

|---|---|---|---|---|

| Quality of Print | High | 150 | 5 | 4.8 |

| Cost Efficiency | Medium | 100 | 7 | 4.5 |

| Customer Service | High | 120 | 3 | 4.9 |

| Reliability | High | 130 | 4 | 4.7 |

| Customization Options | Medium | 110 | 6 | 4.6 |

Ordering in Bulk: Strategies for Cost Savings and Efficiency

When it comes to ordering printed labels for your business, bulk purchasing can yield significant cost savings while enhancing efficiency. By ordering in larger quantities, businesses can often negotiate better pricing with suppliers, reducing the cost per label. Additionally, this strategy helps streamline inventory management, as you can keep a steady supply of labels on hand for various needs, thereby minimizing disruptions in your operations.

To maximize these benefits, it's essential to evaluate your label requirements and forecast your usage accurately. Understanding the types of labels needed for different products or purposes allows for more strategic bulk orders, ensuring you get the most out of your investment. Furthermore, consider engaging with multiple suppliers to compare prices and lead times, which can help secure the most favorable terms. Implementing a just-in-time ordering system can also complement bulk purchasing, allowing businesses to balance cost savings with the need for flexibility and responsiveness in their labeling demands.

Related Posts

-

How to Make Labels at Home Using Easy Methods and Creative Ideas

-

10 Best Us Printing Services for High Quality Custom Prints

-

Top Trends in US Printing for 2025: What You Need to Know

-

Top 10 Incredible Benefits of Using You Printing for Your Business Needs

-

10 Essential Tips for Optimizing Your Industrial Printing Processes

-

What is Craft Labels and How to Use Them for Your DIY Projects