Top 10 You Printing Techniques You Should Know About?

In a world increasingly attuned to personalization, "you printing" stands at the forefront. This technique caters to individual needs and preferences, transforming the way we experience products. Imagine wearing a shirt that showcases your own art, or sipping coffee from a mug that features your unique design. These are not just dreams; they are realizable through advanced printing methods.

Understanding the various "you printing" techniques can elevate your creativity and business opportunities. The ability to print tailored designs opens doors for artists, entrepreneurs, and everyday consumers alike. It’s fascinating, yet many overlook these options thinking they are too complex or costly. There’s a learning curve involved, and it requires experimentation. However, the results can be profoundly rewarding.

Exploring the top printing techniques allows you to choose the right method for your needs. Whether it’s digital printing or screen printing, each has strengths and weaknesses. Take the time to reflect on which technique resonates with you. Embrace the ups and downs of the learning process. Dive into the vibrant world of you printing, where your individuality can shine through unique creations.

Understanding the Basics of Printing Techniques

Understanding various printing techniques is essential for anyone involved in the world of print. Each method has its unique characteristics, making it suitable for different projects. Familiarizing yourself with the basics can enhance your printing knowledge and help you make informed decisions.

Digital printing is one of the most popular methods today. It offers quick turnaround times and is ideal for short runs. However, while it’s efficient, the quality can sometimes vary. It’s important to choose the right materials to ensure the best results.

When considering traditional methods, offset printing stands out for high-quality outputs. It’s perfect for large volumes. But, be mindful of setup costs and longer lead times. Your project’s needs should guide your choice.

Tips: Always ask for samples before committing. Test your designs on various paper types to see how they look. Pay attention to color accuracy, too. Sometimes, it’s the small details that can lead to big changes in the final product. Don't be afraid to experiment to find what works best for your needs.

Exploring Digital Printing: Advantages and Applications

Digital printing has revolutionized the way we create and distribute printed materials. It offers unique advantages over traditional printing methods. The precision in color matching is remarkable. Additionally, digital printing allows for short print runs, which is cost-effective. This is beneficial for businesses that require flexibility. Consider how personalized items can increase customer engagement.

One tip is to choose the right paper. The texture and weight can significantly affect the final output. Another tip is to understand the color profiles. These must align with the printing technology used. For those who want to explore printing processes, trial and error is essential. Don't shy away from testing different techniques. This can lead to unexpected, exciting results.

Digital printing has various applications. From marketing materials to custom art, the choices are endless. It's important to stay updated on emerging technologies. Innovations can enhance creativity and production efficiency. Remember, every technique has its advantages and flaws. Embrace imperfections; they often lead to new ideas and improvements.

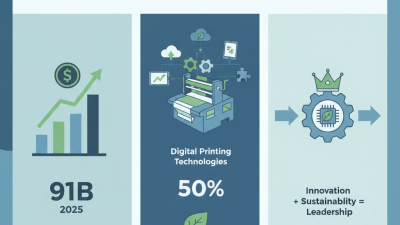

Top 10 Digital Printing Techniques and Their Applications

This chart displays the popularity and applications of various digital printing techniques based on their usage in different industries.

Mastering Offset Printing for High-Quality Outputs

Offset printing remains a dominant technique for achieving high-quality outputs in the printing industry. According to industry reports, offset printing accounts for nearly 40% of total print output worldwide. This method excels at producing vibrant colors and detailed images, making it ideal for brochures, magazines, and large-volume prints. Many operators still grapple with issues like ink consistency and plate wear. These challenges can affect the quality of the final product.

Surprisingly, a recent survey indicated that about 30% of print providers reportedly face problems with color matching. This inconsistency can lead to costly reprints or dissatisfied customers. Mastering offset printing involves not just technical skills, but also an understanding of the materials used, including paper type and ink formulations. Not all printed pieces come out perfect, and frequent adjustments might be necessary during runs to ensure high standards are met. Additionally, some printing facilities overlook regular maintenance of their machines, which can hinder output quality over time. These factors emphasize the importance of continuous learning and adaptation in the world of offset printing.

Unveiling the Power of Screen Printing in Custom Designs

Screen printing is a powerful technique in custom design. It allows vibrant colors and intricate details. According to a report by Smithers Pira, the global screen printing market was valued at approximately $5.3 billion in 2020. This highlights its relevance among small businesses and large brands alike. Many designers favor screen printing for its ability to produce bold, eye-catching graphics.

The process involves pushing ink through a mesh stencil onto the material. This method provides a tactile quality that digital printing often lacks. However, achieving the perfect print requires skill and experience. Minor misalignments can ruin a project. Moreover, not all inks are created equal. Some have environmental concerns that need addressing.

Despite its advantages, screen printing isn't without flaws. The setup time can be lengthy, especially for small orders. This can lead to wasted resources if not managed properly. Furthermore, limitations exist for multi-colored designs due to registration challenges. Learning from mistakes in this craft can be as valuable as the prints themselves. Balancing quality and efficiency remains paramount for anyone working in this field.

The Role of 3D Printing in Modern Manufacturing and Prototyping

3D printing has transformed modern manufacturing and prototyping. It allows for rapid production of complex shapes that traditional methods struggle to achieve. This technology can produce everything from intricate medical devices to custom automotive parts. The ability to create prototypes quickly means that designers can test their ideas sooner.

Despite its advantages, 3D printing isn't without challenges. Material limitations can restrict some designs. Often, the finish quality may not meet expectations. Additionally, production speed can vary significantly based on the printer and material used. This inconsistency is a point of contention for many manufacturers. Understanding these limitations is crucial for businesses looking to adopt this technology effectively.

Flexibility is a key benefit of 3D printing. Companies can adjust designs on the fly. This responsiveness is a game changer in industries that require constant iteration. However, this adaptability can lead to overwhelmed teams trying to balance innovation with production. As companies adopt 3D printing, they must reflect on how to integrate it smoothly into their existing processes.

Related Posts

-

10 Essential Tips for Enhancing Your Printing Experience at Home

-

What is You Printing and How Can It Benefit Your Business?

-

10 Best Us Printing Services for High Quality Custom Prints

-

Top 10 Incredible Benefits of Using You Printing for Your Business Needs

-

Top Trends in US Printing for 2025: What You Need to Know

-

Top Tips for Choosing the Best Printing Shop for Your Needs?