What is Welded Wire Mesh and Its Uses in Construction?

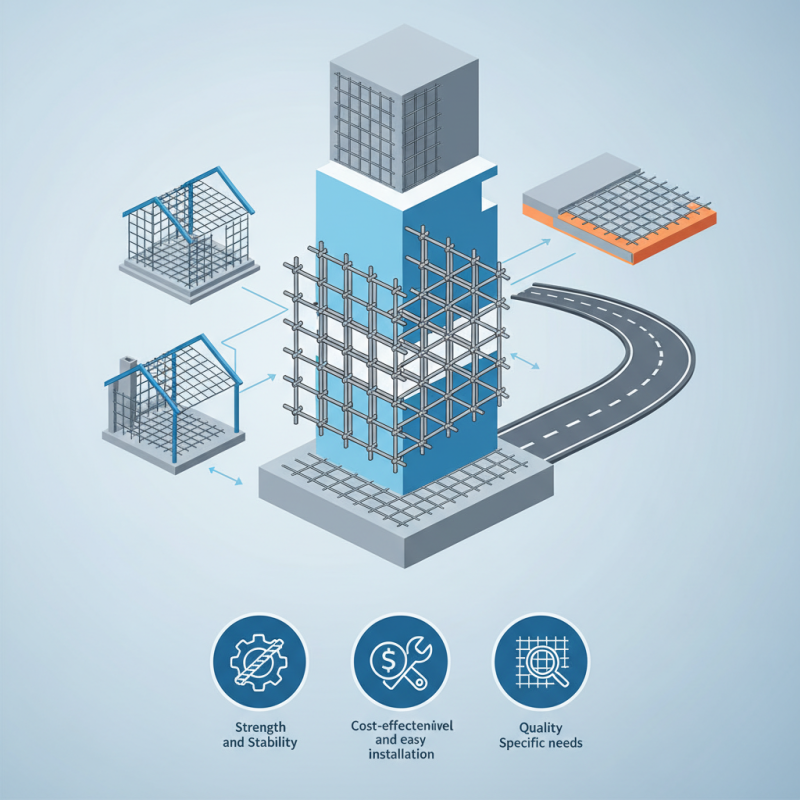

welded wire mesh has become a fundamental component in the construction industry. This product provides strength and stability to various structures, making it essential in building projects. According to industry expert John Smith, “Welded wire mesh ensures the durability and strength of any concrete structure.”

In recent years, its uses have expanded significantly. Builders utilize welded wire mesh in foundations, walls, and even highways. The cost-effectiveness and easy installation make it a popular choice. Yet, challenges exist. Some assume all welded wire meshes are equal, which is misleading. Quality varies widely, depending on the manufacturing process.

Moreover, not all projects require the same type or gauge of mesh. Evaluating specific needs is crucial. When used improperly, it can compromise structural integrity. Awareness and education on the material are essential for optimal application in construction. In short, understanding welded wire mesh can truly elevate building practices.

What is Welded Wire Mesh?

Welded wire mesh is a versatile construction material. It consists of steel wires welded together to form a grid. The wires are usually arranged at regular intervals, creating a robust and uniform structure. According to industry reports, welded wire mesh enhances the durability of concrete structures. It is often used in slabs, walls, and pavements.

In construction, welded wire mesh provides reinforcement. This is crucial for ensuring the longevity of various structures. It helps to distribute loads evenly and resist tension, minimizing cracking. Interestingly, research shows that structures reinforced with welded wire mesh can perform better under stress. This can lead to better safety standards in construction.

**Tip**: When choosing welded wire mesh, consider the spacing and wire diameter based on your specific project requirements.

Some may overlook the importance of mesh quality. Poor-quality wire can lead to failures. It’s essential to ensure that the mesh meets industry standards. Regular inspections can help maintain its integrity.

**Tip**: Always review the specifications before purchase. This will save time and resources in the long run.

Composition and Manufacturing Process of Welded Wire Mesh

Welded wire mesh is a crucial element in construction. Its composition involves steel wires that are welded together at specific intervals. The process starts with selecting high-quality steel rods. These rods are then drawn into wires of appropriate gauges. After that, the wires are cut into desired lengths for welding.

The welding process is quite fascinating. Wires are arranged in a grid pattern. Then, they are welded at intersections using electrical resistance. This step ensures strong bonds and uniform spacing. Notably, the mesh can be galvanized to enhance corrosion resistance. The final product is durable and versatile.

In construction, welded wire mesh serves various purposes. It's commonly used for reinforcing concrete slabs. It helps in distributing load evenly, thus improving structural integrity. However, improper installation can lead to issues. If not laid correctly, it may not provide the intended support. This highlights the need for skilled labor during installation.

Welded Wire Mesh Uses in Construction

Key Characteristics and Benefits of Welded Wire Mesh

Welded wire mesh is gaining traction in the construction industry. This material is a grid of wires that are welded at the intersections. It offers excellent tensile strength and durability. According to a 2023 market report, the global welded wire mesh market is projected to grow by 6% annually. This indicates rising demand in various applications, such as concrete reinforcement.

One key characteristic of welded wire mesh is its versatile nature. It can adapt to different structural needs. The mesh can be produced in various sizes and wire diameters. This customization caters to specific project requirements. Additionally, it provides enhanced stability in construction. The fixed spacing between wires allows for consistent load distribution. However, some users may overlook the importance of choosing the right mesh type, leading to potential structural issues.

The benefits of welded wire mesh extend beyond strength. It is cost-effective and easy to handle. This makes installation quicker and reduces labor costs. A 2022 survey noted that over 70% of builders prefer welded wire mesh for its efficiency. Yet, there are concerns about quality control during manufacturing. Variations in wire thickness or welding techniques can affect performance. Awareness of these factors is crucial for optimal use in construction projects.

Common Applications of Welded Wire Mesh in Construction

Welded wire mesh is widely used in the construction industry. It is made from intersecting wires welded together at their junctions. This product provides structural support and helps improve stability. Construction professionals find it valuable for various applications.

One common use of welded wire mesh is in concrete slabs. It enhances tensile strength and prevents cracking. In addition, it is often employed in walls and barriers. Welded wire mesh also supports paving projects, ensuring a durable surface. Some projects may overlook the mesh's importance. Not using it can lead to issues like shifts and cracks over time.

Another application is in fencing and security. Welded wire mesh creates durable fences that keep intruders out. In landscaping, it can help reinforce soil and control erosion. In some cases, welds may not be perfect, affecting the overall strength. This flaw needs to be considered during installation to avoid future problems. Understanding these uses ensures better decisions in construction planning.

What is Welded Wire Mesh and Its Uses in Construction?

| Application | Description | Advantages |

|---|---|---|

| Concrete Reinforcement | Used to strengthen concrete slabs and walls to prevent cracking. | Improves load-bearing capacity and durability. |

| Fencing | Creates secure perimeters for properties and agricultural areas. | Cost-effective and long-lasting solution for safety. |

| Flooring | Provides a base for various flooring materials, enhancing strength. | Adds structural integrity and minimizes cracks. |

| Retaining Walls | Supports earth and prevents soil erosion. | Effective for managing ground pressure and drainage. |

| Garden Structures | Used in trellises, supports, and fencing for landscaping. | Versatile and easy to install for various designs. |

Factors to Consider When Choosing Welded Wire Mesh for Projects

When selecting welded wire mesh for construction projects, several factors are crucial. The gauge of the wire is one of the primary considerations. Thicker wires provide greater strength, making them more suitable for heavy-duty applications. For smaller projects, thinner wire may suffice, offering flexibility and ease of handling. Additionally, the mesh size plays a significant role. Smaller openings are better for preventing concrete from seeping through, while larger openings allow for easier drainage.

Another aspect to evaluate is the type of coating. A galvanized finish offers protection against corrosion, extending the mesh's lifespan. However, coatings can add to the cost. It's also essential to consider local environmental conditions. Humid areas may require more robust options to combat rust. Lastly, evaluate the project's specific needs. Some uses may need more reinforcement, while others focus on aesthetics. Balancing these factors ensures the right choice for every project.